Only from KHS: freshness protection which is 100% bottle-to-bottle recyclable

The FreshSafe PET coating system provides convincing freshness and quality protection for juices, carbonated beverages, wine or sauces and dressings in PET bottles, for instance. The system also facilitates full bottle-to-bottle recyclability.

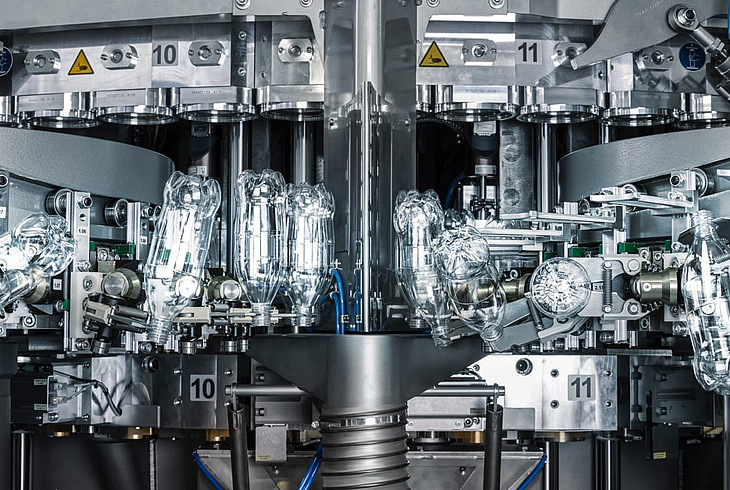

In FreshSafe PET KHS combines the advantages of PET and glass bottles in one, offering market-proven plant engineering for customers with particularly high requirements regarding quality and sustainability. A wafer-thin protective layer of silicon oxide (SiOx) or chemically pure glass finishes the inner wall of the PET container, thus forming an effective barrier: aroma and carbon dioxide are retained while at the same time oxygen is prevented from penetrating the bottle resulting in no loss of vitamins or taste.

Blocked content

This YouTube video is blocked because you have not agreed to the YouTube service. By clicking the button you can change the cookie settings and play the video.

The coating process not only provides long-term product protection and crystal-clear bottles; it also completely does away with the need for additives and therefore enables PET bottles to be fully recycled. With these features KHS is specifically supporting its customers’ efforts to use environmentally-friendly packaging and keep packaging materials in circulation for as long as possible.

Investing in FreshSafe PET technology pays off thanks to lower operating costs and a number of further economic benefits. With FreshSafe PET bottlers can switch to less expensive standard PET preforms, for instance. In order that each customer can study the advantages for themselves, KHS provides a customized total cost of ownership calculation based on the use of barrier technology.

Blocked content

This YouTube video is blocked because you have not agreed to the YouTube service. By clicking the button you can change the cookie settings and play the video.

Maximum freshness protection, long shelf lives and lower overall costs

FreshSafe PET protects sensitive products such as fruit juices and nectars just as reliably as carbonated beverages. The freshness and taste are retained while the shelf life is considerably lengthened. It is therefore also worth using the barrier system, for example, when small bottles (holding less than 500 ml) have to travel long distances and are subjected to changing climatic conditions.

Pure PET for reuse – official recognition

Fruit juice bottles in particular often contain multilayer, blended or scavenger additives. These protect sensitive beverages from external influences yet often prevent pure-grade recycling of the PET material. With FreshSafe PET KHS provides the only fully recyclable barrier system currently available. In the recycling process the glass coating is simply washed off by the caustic in a standard procedure. This produces pure, separated PET which can be fully recycled. Using this method PET bottles made of recyclate can also be coated without restriction.

This unique recyclability is acknowledged by the Association of Plastic Recyclers (APR) label, among others (more in our press release on the subject). In its design guidelines the European PET Bottle Platform (EPBP) also describes KHS’ transparent SiOx coating technology as the only fully compatible barrier technology for PET bottles.

„A product is only successful when it solves a relevant problem. With FreshSafe PET we have created an environmentally-friendly and cost-efficient system which combines sustainability with the best possible product protection.“

„A product is only successful when it solves a relevant problem. With FreshSafe PET we have created an environmentally-friendly and cost-efficient system which combines sustainability with the best possible product protection.“

Bernd-Thomas Kempa, Head of Global Account Management Plasmax Barrier Technology

Benefits of FreshSafe PET

Product protection

The wafer-thin layer of glass reliably protects sensitive products or carbonated beverages against loss of freshness and quality – and thus makes a major contribution to the protection of the environment. For the more reliable the product protection, the lower the amount of food wasted.

Shelf life

With FreshSafe PET no unwanted substances enter the PET bottle from the outside – and valuable ingredients such as vitamins cannot escape. In this way the innovative technology can make product shelf lives up to ten times longer.

Bottle-to-bottle recyclability

With FreshSafe PET KHS provides the only fully recyclable barrier system currently available on the market. This has been confirmed by a number of recycling associations such as the EPBP and APR.

Flexible application

The product protection provided by FreshSafe PET makes the PET container with its diverse inherent advantages – such as low weight and unbreakability – a particularly intelligent form of packaging. Not only beverages profit from FreshSafe PET but also sauces and dressings, preserved foods and, last but not least, small containers holding less than 500 ml.

Cost/benefit ratio

Investing in this innovative technology pays off relatively quickly: bottlers can switch to less expensive standard PET preforms and the overheads at the plant fall, so that the total cost per bottle is actually lower.

Recyclate coating

FreshSafe PET barrier technology is also suitable for coating PET bottles made of recyclate (rPET) and for biodegradable containers. This means that the barrier system scores on sustainability not just once but twice.